All piping systems had to be purged with nitrogen and flushed with water prior to removal. TIS decontaminated and removed over 75,000 pounds of stainless steel piping, 12 stainless steel chemical storage tanks, and two 60-foot solvent distillation columns.

Especially challenging was that many of the piping systems to be removed were mixed in with active chemical delivery piping systems. Careful planning and extreme care was taken to keep from damaging active systems.

TIS worked closely with the owner’s engineers and other trades on this successful project. TIS completed the project 3 weeks ahead of schedule and significantly under the $500,000 budget for our portion of the work. No accidents, injuries, exposures, or shut-downs were experienced on this very successful decontamination/demolition project. TIS prides itself on having a top-notch safety record despite the variety of challenges faced daily.

All piping systems had to be purged with nitrogen and flushed with water prior to removal. TIS decontaminated and removed over 75,000 pounds of stainless steel piping, 12 stainless steel chemical storage tanks, and two 60-foot solvent distillation columns.

Especially challenging was that many of the piping systems to be removed were mixed in with active chemical delivery piping systems. Careful planning and extreme care was taken to keep from damaging active systems.

TIS worked closely with the owner’s engineers and other trades on this successful project. TIS completed the project 3 weeks ahead of schedule and significantly under the $500,000 budget for our portion of the work. No accidents, injuries, exposures, or shut-downs were experienced on this very successful decontamination/demolition project. TIS prides itself on having a top-notch safety record despite the variety of challenges faced daily.

Environmental Management, News

Decommissioning and Decontamination

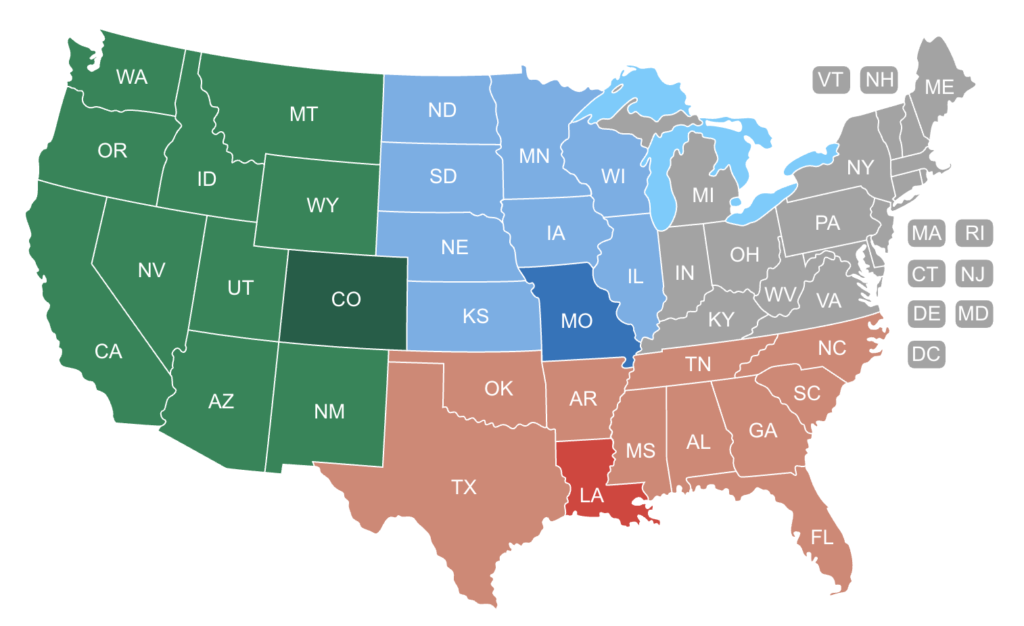

Description: One of our clients decided to remove chemical process systems no longer being utilized at their toner and developer manufacturing facility located near Boulder, Colorado. TIS was contracted to decontaminate and demolish all chemical piping, process vessels, and chemical storage tanks no longer needed. The piping and vessels contained ethylenediamine, butyl amine, toluene, and THF – to name a few.

All piping systems had to be purged with nitrogen and flushed with water prior to removal. TIS decontaminated and removed over 75,000 pounds of stainless steel piping, 12 stainless steel chemical storage tanks, and two 60-foot solvent distillation columns.

Especially challenging was that many of the piping systems to be removed were mixed in with active chemical delivery piping systems. Careful planning and extreme care was taken to keep from damaging active systems.

TIS worked closely with the owner’s engineers and other trades on this successful project. TIS completed the project 3 weeks ahead of schedule and significantly under the $500,000 budget for our portion of the work. No accidents, injuries, exposures, or shut-downs were experienced on this very successful decontamination/demolition project. TIS prides itself on having a top-notch safety record despite the variety of challenges faced daily.

All piping systems had to be purged with nitrogen and flushed with water prior to removal. TIS decontaminated and removed over 75,000 pounds of stainless steel piping, 12 stainless steel chemical storage tanks, and two 60-foot solvent distillation columns.

Especially challenging was that many of the piping systems to be removed were mixed in with active chemical delivery piping systems. Careful planning and extreme care was taken to keep from damaging active systems.

TIS worked closely with the owner’s engineers and other trades on this successful project. TIS completed the project 3 weeks ahead of schedule and significantly under the $500,000 budget for our portion of the work. No accidents, injuries, exposures, or shut-downs were experienced on this very successful decontamination/demolition project. TIS prides itself on having a top-notch safety record despite the variety of challenges faced daily.

All piping systems had to be purged with nitrogen and flushed with water prior to removal. TIS decontaminated and removed over 75,000 pounds of stainless steel piping, 12 stainless steel chemical storage tanks, and two 60-foot solvent distillation columns.

Especially challenging was that many of the piping systems to be removed were mixed in with active chemical delivery piping systems. Careful planning and extreme care was taken to keep from damaging active systems.

TIS worked closely with the owner’s engineers and other trades on this successful project. TIS completed the project 3 weeks ahead of schedule and significantly under the $500,000 budget for our portion of the work. No accidents, injuries, exposures, or shut-downs were experienced on this very successful decontamination/demolition project. TIS prides itself on having a top-notch safety record despite the variety of challenges faced daily.

All piping systems had to be purged with nitrogen and flushed with water prior to removal. TIS decontaminated and removed over 75,000 pounds of stainless steel piping, 12 stainless steel chemical storage tanks, and two 60-foot solvent distillation columns.

Especially challenging was that many of the piping systems to be removed were mixed in with active chemical delivery piping systems. Careful planning and extreme care was taken to keep from damaging active systems.

TIS worked closely with the owner’s engineers and other trades on this successful project. TIS completed the project 3 weeks ahead of schedule and significantly under the $500,000 budget for our portion of the work. No accidents, injuries, exposures, or shut-downs were experienced on this very successful decontamination/demolition project. TIS prides itself on having a top-notch safety record despite the variety of challenges faced daily.