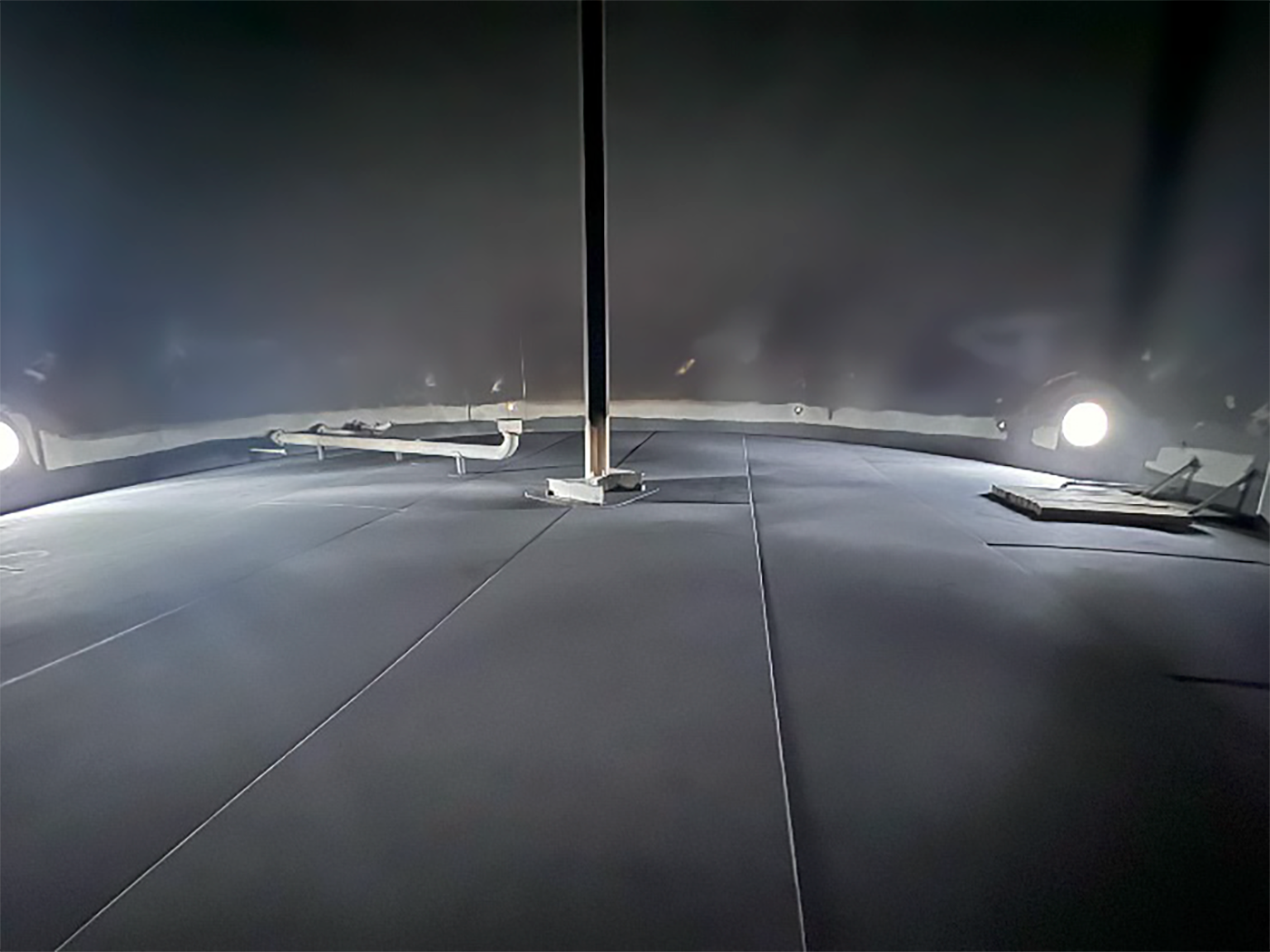

TIS was contacted by a midstream pipeline client to abrasive blast a 42.5’ diameter diesel tank in Lincoln, NE. The tank was emptied, cleaned, and taken out of service due to API 653 10-year inspection requirements. The primary objective of TIS was to blast the interior surfaces, including the entirety of the floor and leave the tank inspection ready.

TIS was contacted by a midstream pipeline client to abrasive blast a 42.5’ diameter diesel tank in Lincoln, NE. The tank was emptied, cleaned, and taken out of service due to API 653 10-year inspection requirements. The primary objective of TIS was to blast the interior surfaces, including the entirety of the floor and leave the tank inspection ready.

After the system was verified in working order and the tank atmosphere was checked, two TIS entrants donned a blast hood with PAPR respirator, Nomex coveralls with wrist and ankles taped; blast gloves with gauntlets, steel toed leather boots and entered the tank to begin blasting.

The tank had been previously cleaned by TIS, so we were cleared to stage equipment including an 8-ton blast pot, 1,600 CFM media dryer, and a 900 CFM air compressor. Once the equipment was staged, a 2-ton super sack of blast media was loaded into the blast pot with a telehandler, and all hoses were hooked up.

The tank had been previously cleaned by TIS, so we were cleared to stage equipment including an 8-ton blast pot, 1,600 CFM media dryer, and a 900 CFM air compressor. Once the equipment was staged, a 2-ton super sack of blast media was loaded into the blast pot with a telehandler, and all hoses were hooked up. The thickness of the coating on the tank floor was, on average 40 mls thick, and therefore it took approximately 7 days of blasting to complete. During the process, when the spent blast media was piling up and in the way, the crew would spend half a day to shovel the spent media out and put back into super sacks for disposal by the client at a later date. Both the initial cleaning and the blasting were completed by TIS which required less contractors and mobilizations and therefore saved our client money.

The thickness of the coating on the tank floor was, on average 40 mls thick, and therefore it took approximately 7 days of blasting to complete. During the process, when the spent blast media was piling up and in the way, the crew would spend half a day to shovel the spent media out and put back into super sacks for disposal by the client at a later date. Both the initial cleaning and the blasting were completed by TIS which required less contractors and mobilizations and therefore saved our client money.