TIS was contacted by a midstream pipeline client to abrasive blast a 42.5’ diameter diesel tank in Lincoln, NE. The tank was emptied, cleaned, and taken out of service due to API 653 10-year inspection requirements. The primary objective of TIS was to blast the interior surfaces, including the entirety of the floor and leave […]

Author Archives: Brian Johnson

Shawn Burress, Manager of TIS Environmental, Inc’s OSHA and HazMat Training Services, was contracted by a Class I railroad client to consult with U.S. and Mexico-based Railroad HazMat Managers on the safe handling of lithium battery packs in 20 Ford Mach-E electric cars that were involved in a grade crossing accident-related fire near Monterey, Mexico. […]

TIS sourced and managed an API 653 Robotic Internal Inspection of a 115 foot diameter red-dyed diesel tank for a railroad client located at their central Oklahoma fueling facility. The robotic inspection approach was chosen to keep from having to take the tank out of service, empty it, and clean it prior to performing the […]

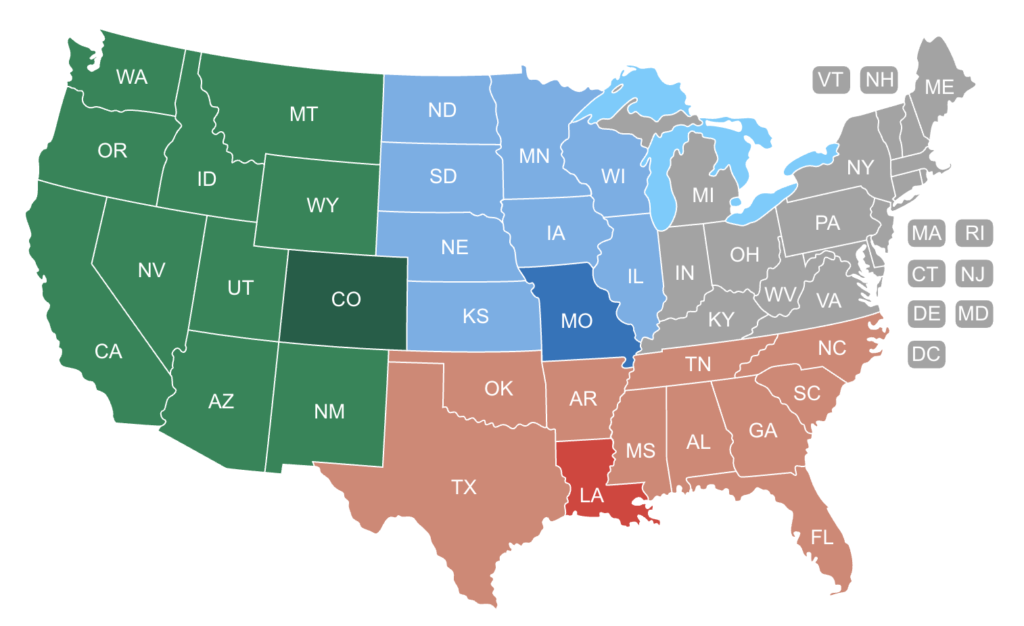

Description: TIS was contacted by a midstream pipeline client to clean a 42.4’ diameter fire water tank in Jefferson City, MO. The tank was emptied, cleaned, and taken out of service due to API 653 10-year inspection requirements. The primary objective of TIS was to clean the interior surfaces and leave the tank inspection ready. […]

Description: TIS was contacted by a midstream pipeline client to isolate & clean a 52’ diameter gasoline tank in Lincoln, NE. The tank was emptied, cleaned, and taken out of service due to API 653 10-year inspection requirements. The primary objective of TIS was to remove any trace of explosive vapors/material and leave the tank […]

Description: TIS was contacted by a midstream pipeline client to repair/replace the missing and damaged geodesic roof vent screens of a 73.5’ transmix tank. The lack of effective screening (Picture 1) in areas allowed birds to access the area above the steel Internal Floating Roof (IFR), causing a bird waste issue for Terminal workers. This […]

Description: On Wednesday August 19th, 2020 TIS mobilized a three-person crew to a manufacturing facility in Boulder, CO to perform maintenance on two storm water retention basins that had accumulated water-born algae and other solid material. TIS started the project by verifying the basin pumps were turned off, de-energized and locked out. TIS then went […]

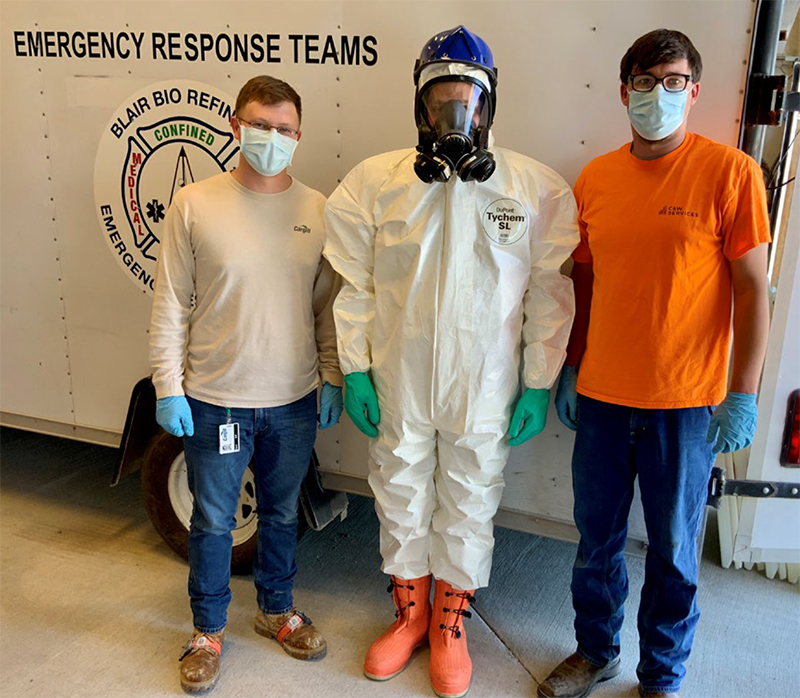

Description: Shawn Burress, Manager of Training Services from our Omaha office, conducted a 24 Hour HAZWOPER Hazardous Materials Technician class in Nebraska at a client facility. The goal is to assist in preparing their personnel for uncontrolled releases of hazardous substances in compliance with EPA mandated Facility Response Plans. This is the first multi-day onsite […]

On Friday, June 5, 2020, TIS arrived at the Spokane Terminal to repair/replace a manway gasket on an above ground storage, external floating roof. Though the manway had been previously repaired with a Belzona brand industrial composite around the edge of the flanges, over time a small leak would be observed when the external floating […]

Our client, an EPA Large Quantity Generator, asked TIS in January 2020 to evaluate the waste streams at their manufacturing facility in Sedalia, Missouri. A hazardous waste determination must be kept on site, as required by 40 CFR 262.11 (f), for at least three years from the date of the last shipment of hazardous waste. […]